Engines

Choosing the right type of engine and propeller for your boat is very important. The engine’s weight and horsepower will have an impact on the performance of your boat. Matching the correct size and pitch for the propeller will enable your boat and engine to achieve the maximum performance for which it was designed. Most good dealers will guide you in these selections, but knowing what questions to ask is essential to getting exactly what you want.

Engine Types

Outboard Motors

An outboard motor is mounted on the boat’s transom outside of the hull at the stern, or back of the vessel. An outboard’s gearcase and propeller is submerged during operation but can be tilted out of the water when not in use. This prevents uneccessary corrosion or marine growth and makes them ideal for salt or freshwater use. To steer an outboard, the engine is pivoted on its mount, directing the propeller’s thrust. Today's outboard motors range in horsepower from 2.5 HP to over 350 HP per engine. But a few are now available boasting over 500 horsepower.

In the past, outboards were typically conventional two-stroke engines, but manufacturers have since switched to environmentally friendly low-emission engines which include direct fuel injection (DFI) two-stroke and four-stroke designs. Conventional two-stroke engines required oil to be mixed with gasoline to lubricate the engine, while DFI two-stroke engines and four-stroke engines require the oil and gasoline to be separate. Modern low-emission marine outboard engines, in addition to running quieter and smoother, are more environmentally friendly, as the exhaust they emit is virtually smokeless compared to conventional two-strokes.

New outboards meet stringent new EPA emissions regulations that also serve to make them much more fuel efficient than early outboards. Some manufacturers use a “four-stroke” engine design and others use a modern two-stroke design called direct fuel injection(DFI). Four strokes are much like your auto engine and have an oil reservoir and a dipstick to check the levels

Two stroke engines use targeted injection that draws oil from a reservoir to oil critical parts of the engine during operation. The oil is consumed with the fuel leaving no residue. Modern low-emission marine outboard engines run quieter and smoother and with virtually smokeless exhaust when compared with engines of fifteen years ago.

Direct Fuel injection (DFI) Outboards

Fuel is injected directly into the combustion chamber and ignited by the spark plug. The fuel spray from the fuel injector is highly atomized and quickly lowers the temperature of the combustion chamber, allowing for increased engine power, low fuel consumption and low emissions. Direct fuel injection results in no fuel priming, quick engine starting, and precision engine speed and performance across the operating range of the engine. Many of today’s most sophisticated automotive engines use a combination of DFI and four-stroke designs.

Electronic Fuel Injection(EFI)

Fuel is injected into the incoming air for each cylinder, just prior to the intake valve of the engine. The fuel spray from the injector contacts the hot intake valve, cooling the valve and increases the vaporization of the fuel prior to being introduced into the combustion chamber. A spark plug then ignites the fuel air mixture. Electronic fuel injection results in no fuel priming, quick engine starting, low emissions and fuel consumption, and robust engine performance across the operating range of the engine.

Carbureted Fuel Induction

A carburetor is the most basic type of fuel induction system and is a cost effective way to control the fuel delivery to the engine. However, some modern 4-stroke outboard engines outfitted with carburetors are calibrated to meet all applicable exhaust emission standards and offer greatly improved fuel economy over older 2-stroke carbureted engines.

Automobile Engine Onboard

Marine gas engines are automotive engines modified for use on the water. Gasoline stern drive and inboard engines range in horsepower from 135 HP to over 1000 HP per engine and are used in a variety of boats

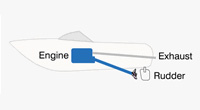

Inboard Engines

Inboard engines have the engine and transmission mounted within the hull of the boat, under the deck. A drive shaft extends through the hull and a propeller is mounted on it to drive the engine. Steering is accomplished by using a rudder.

Gas Sterndrive Engines

Sterndrives combine the gearcase of an outboard with the engine of an inboard. In fact, history indicates the sterndrive engine was inspired by outboard designs. A sterndrive’s gearcase extends through the transom at the back of the boat and the and a series of gears redirect the drive shaft below the water. The result is a propeller perfectly aligned with the boat’s direction of travel. Steering is accomplished by moving the propeller from left to right. The drive unit can also be tilted up for trailer travel. On smaller boats, when outboards are not selected, sterndrives are often the choice of power.

Pod Drive Engines

Since 2004, engine makers have been building a new form of marine propulsion called Pod Drives. These feature inboard engines—usually diesel—with a transmission inside the hull behind the engine. The transmission uses a downward oriented shaft that goes through the pod housing into the water to the gear case tucked up in front of the transom. The pod drive pivots to direct thrust. These engine systems offer more thrust per horsepower because they are perfectly aligned to the keel of the boat, making all force go in line with the boat’s motion. By contrast, inboard boats have a shaft that goes through the hull at an angle that turns the propeller downward by several degrees. Some of the thrust is lost to this downward orientation. Pod drives incorporate special steering and throttle systems that are entirely electronic. They are integrated with GPS systems on board and auto pilots for easy course plotting. Station keeping is a feature that allows the boat to maintain its position—say while you fit fenders and lines to moor the boat—until you return to the helm. The engine systems are more expensive, but save considerable space onboard, adding the possibility of an additional cabin or entertainment room. They are designed to shear off on impact in a grounding, sparing much damage to the hull and making getting back underway as easy as possible.

Diesel Inboard Engines

Diesel engines rely on compression to ignite the fuel and power the engine. Diesel engines are widely used in other parts of the world but in the United States, they are typically only found in boats larger than 35 feet due to their improved fuel efficiency weighed against an initial higher cost. In recent years, fuel and emissions regulations from the EPA and EU have revolutionized the diesel engine creating more efficient and cleaner engines.

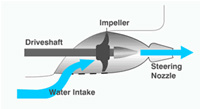

Jet Boat and Personal Watercraft Engines and Propulsion

A marine jet drive system is much different than an outboard or sterndrive or inboard which uses a propeller in the water. A jet boat and personal watercraft draws water from under the boat into a pump inside the boat and then expels it through a nozzle at the stern

Jet boats and personal watercraft are highly maneuverable and have very fast acceleration and because they have no exposed propeller below the surface can often run safely in shallower water.

Size Matters

Surveys show the most likely reason a boater becomes disenchanted with his new boat is for lack of horsepower. Ensure that the motor you choose is the ideal horsepower for your vessel and the activities you want to pursue. Often the choice of power is over-simplified by the question “How fast will it go?” More horsepower gives far more than speed. It gives better handling at midrange speeds, a better “hole shot” for pulling skiers from the water and often better sea keeping capabilities in rough water

A boat that may give a satisfactory test run with you and the dealer and 10 gallons of fuel may be completely unacceptable with a maximum passenger load, a cooler of drinks and a full tank of gas.

A good rule is to get the horsepower as possible to the maximum your boat is rated for. And added penalty for too little horsepower is excessive fuel consumption. It seems like a smaller engine should burn less, but typically, it has to work harder to give the performance you expect and it burns more gas doing it. Which horse will have an easier time of carrying a 200-lb rider? A smaller, slimmer horse or a stronger, more powerful horse?

Choosing the right type of engine and propeller for your boat is very important. The engine’s weight and horsepower will have an impact on the performance of your boat. Matching the correct size and pitch for the propeller will enable your boat and engine to achieve the maximum performance for which it was designed. Most good dealers will guide you in these selections, but knowing what questions to ask is essential to getting exactly what you want.

Choosing the Right Engine Package

Choosing the right type of propulsion system for your boat is a very important matter. Its weight and horsepower will both have an impact on the performance of your vessel. If your vessel is underpowered, its engine will work hard continually and will provide poor performance. Additionally if your vessel is overpowered, it may exceed the safe operating speed that was designed for the vessel.

- Outboard Motors - 2 stroke

- Outboard Motors - 4 stroke

- Diesel Inboard Engines

- Gas Inboard Engines

- Jet Boat Engines and Propulsion

- Stern Drives

Size Matters

When you're choosing the appropriate power for your boat, consider the size and weight of the boat and remember that weight includes your passengers, fuel and gear.

A good rule of thumb is to come as close as possible to the maximum horsepower that your boat is rated for.

Both weight and horsepower will have an impact on the performance of your vessel. If your vessel is underpowered, your engine will work harder than it needs to, possibly leading to more routine maintenance. The boat will also not perform to your expectations which may leave you unhappy with the boat. This may also lead to higher fuel consumption.

Additionally, if your vessel is overpowered, it may exceed the safe operating speed that was designed for the vessel. Manufacturers and dealers will all have a recommended power package for each and every boat that they manufacture and sell.

Pick Your Power

When looking at gasoline engines (outboard, stern drive or inboard), there are three distinct types of fuel delivery systems on the market. They are: Direct Fuel Injection (DFI), Electronic Fuel Injection (EFI) and Carbureted.

Each fuel delivery system is unique in its own way and there are benefits to each system.

Direct-Fuel-Injection (DFI)

In a direct fuel injection system, the fuel is directly injected into the engine's cylinders. This helps control and raise fuel economy and compression ratios in relation to the engine's overall performance. High pressure fuel pumps and fuel injectors are a couple of the key components when looking at the system.

Benefits

- Low emissions

- Excellent fuel economy

- Instant turn key starting

- Smooth idling

- Reduced vapor lock in warmer climates

- Ability to automatically adjust to altitude, air and water temperatures

- Superior throttle response and power

- Availability of self diagnosis systems

- Sealed fuel system (helps to eliminate fuel oxidation)

Electronic Fuel Injection (EFI)

Electronic Fuel Injection functions on three basic systems; fuel delivery system, air induction system, and the electronic control system.

The fuel delivery system maintains a constant pressure through the use of an electronic fuel pump. The air delivery system controls the amount of air needed to burn the fuel efficiently. Finally, the electronic control system or some times called the ECU unit controls the fuel injectors and determines how much fuel and air needs to be delivered into cylinders at any given time.

Benefits

- Uniform air and fuel distribution

- Superior throttle response and power

- Usually excellent fuel economy

- Cold engine start ability

- Availability of self diagnosing systems

- Low emissions (especially 4-stroke)

Carbureted Fuel Systems

Carbureted engines have been around for several decades now. When looking at a carbureted engine, you will notice the carburetor on top of the engine. The carburetor controls the amount of air flow and fuel into the engine. This is a mechanical process that is controlled by a throttle body cable that is usually hooked to the throttle at the helm. Again, this is an all mechanical process.

Benefits / notes

- Lowest initial cost

- Simple by design

- Higher emissions than an EFI or DFI system

- Poor fuel economy when compared to an EFI or DFI system